Process Engineer

Proceess Engineer for Paint & Molding

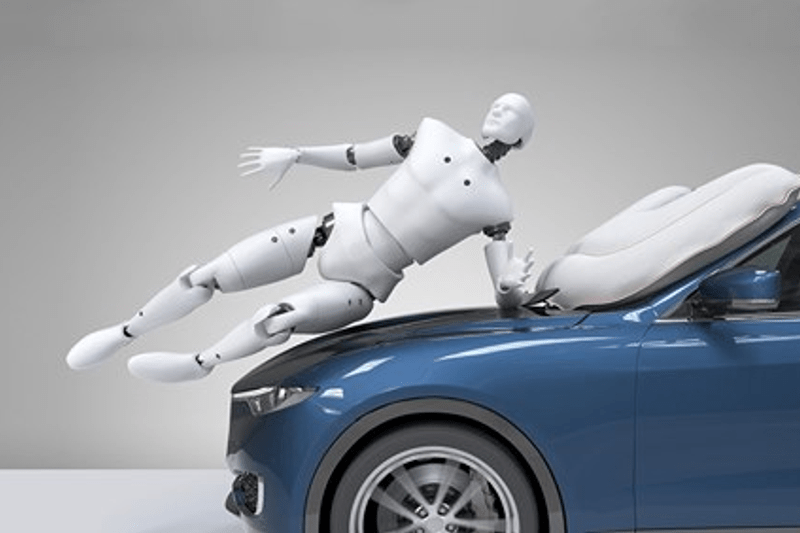

Autoliv, Inc., a world leader in development and manufacture of automotive safety is currently accepting resumes for a Process Engineer in the Painting Operation at the Autoliv Module Facility in Ogden, UT.

What you’ll do:

- Oversees the complexities associated with the maintenance, repair and design improvements of automated paint equipment and robotics.

- Operates paint process and application equipment in accordance with established control plans and specifications in order to satisfy the customer quality standards and delivery schedule.

- Communicates and collaborates with paint and equipment suppliers to optimize usage, ensure formulation compatibility, and address paint performance and quality concerns across current and future programs.

- Reviews existing paint processes and recommends modifications based on customer requests and evolving project requirements.

- Partners with customers to meet technical specifications and enhance efficiency, quality, and product characteristics in line with program goals.

- Utilizes problem solving tools (8D, Fishbone, 5 Why) to solve and eliminate problems and variation.

- Responsible for complex paint mixing and ensuring accurate product inventory of the paint.

- Demonstrates competence and provides expertise in the utilization of solvent based 1K and 2K PU paints, fluid delivery systems, and robotic liquid coating application equipment and processes.

- Demonstrates proficiency in trouble-shooting appearance and performance issues as well as training others in problem identification and resolution.

- Ensures proper handling of paints and solvents per waste handling regulations. Performs process equipment specification development.

- Utilizes and demonstrates proven ability to set up a paint kitchen capable of quick change-over

- Utilizes advanced software tools for technical analysis and process evaluation to support operational improvements.

- Prepares detailed justification documentation for capital expenditure proposals, ensuring alignment with business goals and return on investment expectations.

- Supports the ongoing development of Process FMEAs. Maintains the organization and 5S of the paint vault in the Paint Facility.

What is required:

- Bachelor’s degree in industrial, Mechanical, Manufacturing, Process, or Product Engineering, with strengths in fluid dynamics.

- Hands on competence with robotic programming is preferred

- Solid Works experience and hands on mechanical aptitude preferred

What’s in it for you:

•Attractive compensation package

•Flexible Options (schedule, etc)

•Recognition awards, company events, family events, university discount options and many more perks.

•Gender Pay Equality

Autoliv is proud to be an equal opportunity employer. Autoliv does not discriminate in any aspect of employment based on race, color, religion, national origin, ancestry, gender, sexual orientation, gender identify and/or expression, age, disability, or any other characteristic protected by federal, state, or local employment discrimination laws where Autoliv does business.

- Function

- Industrial Engineering

- Locations

- Ogden - Assembly (AOA)

Ogden - Assembly (AOA)

Workplace & Culture

We strive to save more lives and prevent serious injuries, and we continuously focus on quality, confidence and security for our customers, stability and growth for our shareholders and employees, as well as being sustainable and earning trust within our communities.

About Autoliv United States

Autoliv is the worldwide leader in automotive safety systems. Through our group companies, we develop, manufacture and market protective systems, such as airbags, seatbelts, and steering wheels for all major automotive manufacturers in the world as well as mobility safety solutions.

At Autoliv, we challenge and redefine the standards of mobility safety to sustainably deliver leading solutions. In 2024, our products saved 37,000 lives and reduced 600,000 injuries.

Our ~65,000 colleagues in 25 countries are passionate about our vision of Saving More Lives and quality is at the heart of everything we do. We drive innovation, research, and development at our 13 technical centers, with their 20 test tracks.

Process Engineer

Loading application form